BOWLING BALL BASICS

Bowling balls are crafted with combinations of three components to achieve specific performance goals. Understanding the coverstock, core, and weight block is essential for selecting the right bowling ball to suit your playing style and skill level.

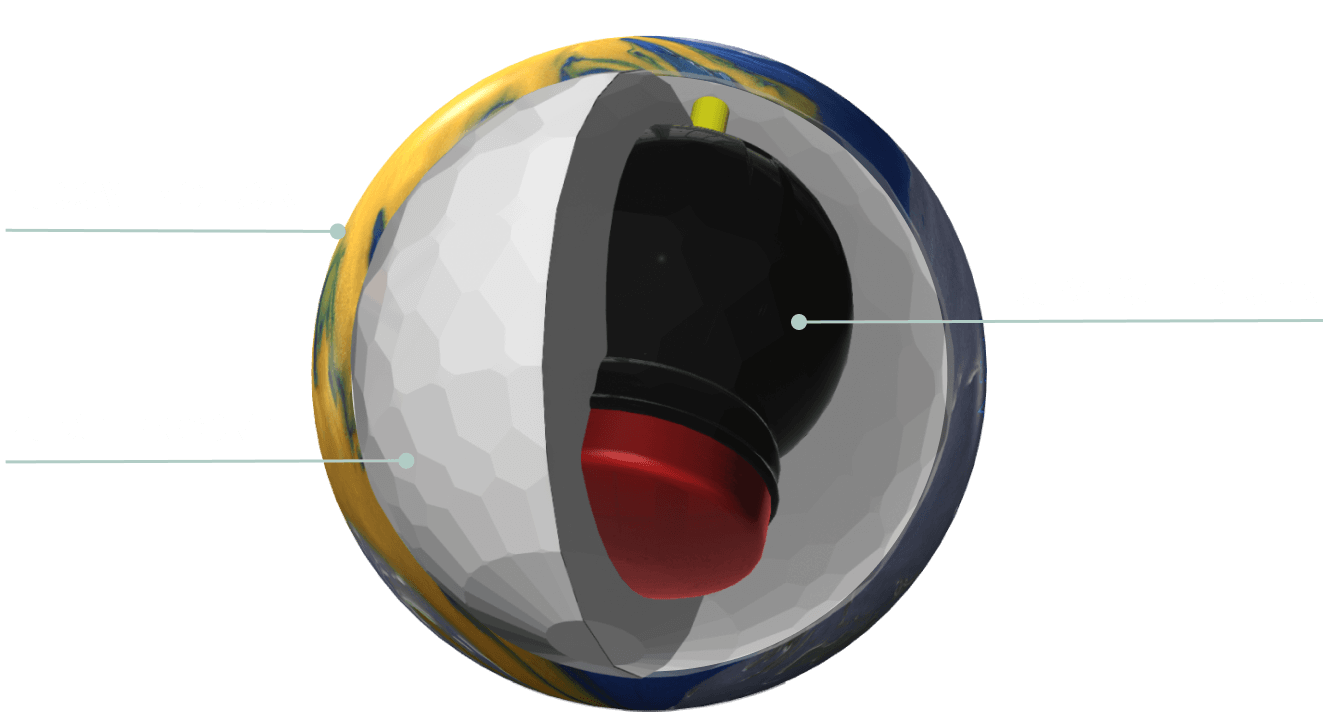

Anatomy of A Bowling Ball

1. COVER

The coverstock is the outermost layer of the bowling ball, and it directly contacts the lane's surface. It is responsible for the ball's gripping ability and reaction to the oil on the lane.

4 TYPES

Depending on the coverstock material and its surface finish, a bowling ball can be designed to skid, hook, or roll smoothly. The coverstock is a critical factor in controlling the ball's trajectory and hitting the pins with precision.

Solid

A solid coverstock offers reliable and controllable ball motion, ideal for various bowlers and lane conditions, especially on medium to heavy oil patterns.

Hybrid

Hybrid coverstock on a bowling ball blends solid and pearl features, delivering versatility with a strong midlane read, extended skid, and powerful backend hook.

Pearl

Pearl coverstock on a bowling ball shines with an extended skid phase, powerful backend hook, and is a versatile choice for dry to medium-oiled lanes, favored for its dynamic ball motion.

Urethane

Urethane bowling balls provide a smooth, controllable motion on the lane. Known for their predictability, they offer a gradual hook, making them favored by bowlers who prefer a traditional style. They excel on shorter oil patterns, where aggressive balls may overreact.

SURFACE VARIATIONS

Bowling ball surface changes are essential adjustments made to the coverstock of a bowling ball, primarily through sanding and polishing. These changes can significantly impact a ball's performance on the lane, making them a critical part of a bowler's strategy.

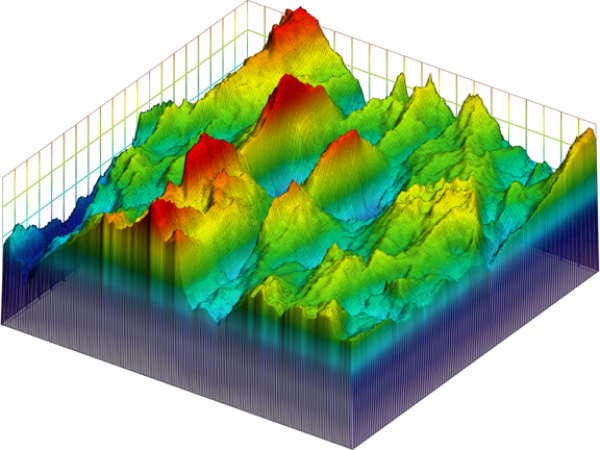

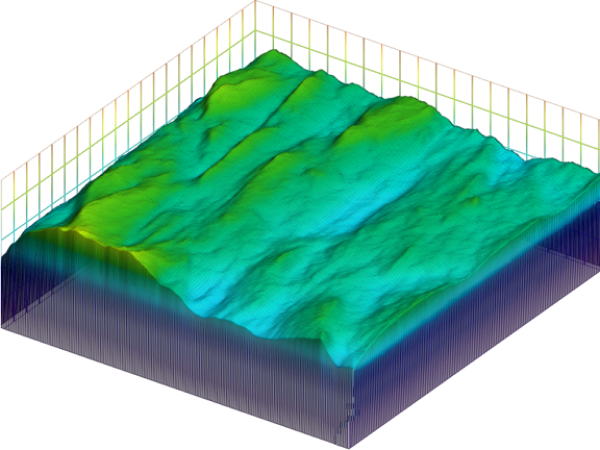

ROUGH EDGE

- Description: A rougher surface created by lower grit sanding.

- Effect: Increases friction with the lane.

- Performance: Causes the ball to hook earlier.

- Ideal Conditions: Best suited for heavy oil patterns.

MEDIUM EDGE

- Description: A moderately sanded surface, balancing roughness and smoothness.

- Effect: Offers a blend of friction and skid.

- Performance: Provides a balanced hook motion.

- Ideal Conditions: Suitable for medium oil patterns.

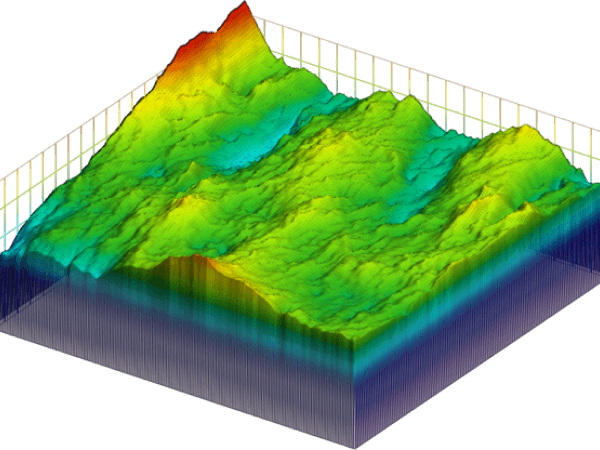

SMOOTH EDGE

- Description: A smoother surface created by higher grit sanding.

- Effect: Reduces lane friction.

- Performance: Allows the ball to skid further before hooking.

- Ideal Conditions: Ideal for medium-to-dry lane conditions.

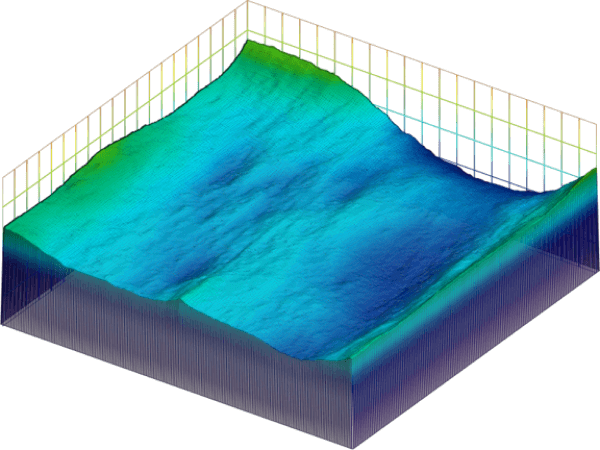

REACTA GLOSS

- Description: A polished surface with minimal roughness.

- Effect: Significantly reduces friction for maximum skid.

- Performance: Delivers a delayed hook reaction for precise control.

- Ideal Conditions: Designed for dry or light oil patterns.

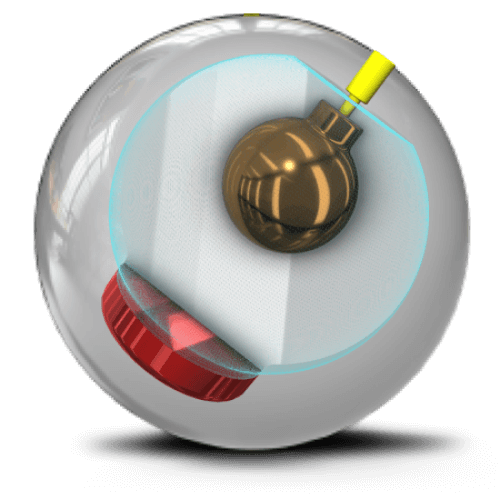

2. OUTER CORE

In between the coverstock and the weight block of a bowling ball, there is a material called the outer core. The filler material is typically made of a light substance such as a polyurethane foam or a resin material. It is the least dense out of the three parts.

3 TYPES

The filler material serves as the transition between the weightblock and the coverstock and creates a bond btween the two, helping it maintain its shape and structural integrity.

Traditional

The core is filled with a blend of glass microbubbles and denser filler, a crafty concoction that enables the manufacturer to customize the ball's weight without compromising its 27-inch circumference.

Inverted FE²

This configuration optimizes energy transfer upon impact, leading to improved pin carry and hitting power.The unique design of the core ensures lane consistency, enabling precise adjustments and predictable reactions, making it an optimal choice for bowlers seeking peak performance.

AI Core

Our cutting-edge AI core technology extends the margin of error in the pocket, elevating carry percentages even on those less-than-perfect shots that might miss the pocket slightly. This new technology helps Storm engineers manipulate the densities inside the bowling ball with more precision. Learn more about AI Core

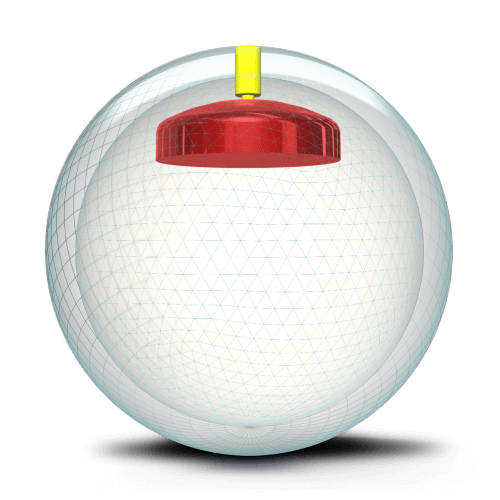

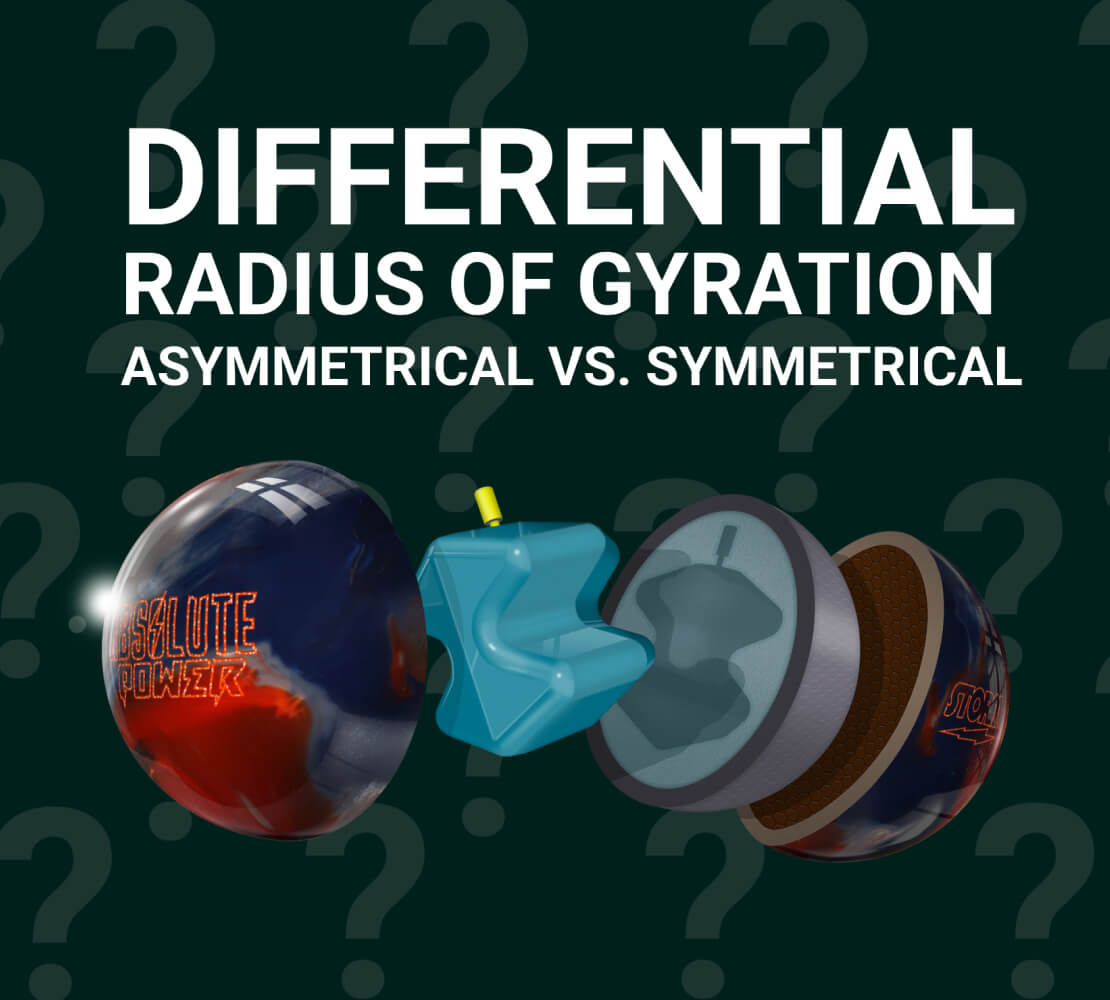

3. WEIGHTBLOCK

The weight block of a bowling ball is a crucial internal component responsible for the ball's weight distribution and its overall dynamics. It plays a significant role in determining the ball's motion on the lane.

3 TYPES

Weight blocks come in various shapes and designs, each designed to produce specific ball reactions. The three primary categories of weight block shapes are traditional 3 piece weightblocks often called a pancake blocks, symmetric and asymmetric.

Pancake

A flat, circular disk within the ball, particularly found in polyester spare balls. This core design is renowned for its smooth and predictable ball motion, minimizing overall flare potential Bowlers often use balls with pancake cores for picking up spares due to their reliable motion on the lane.

Symmetric

Symmetric cores have a balanced weight distribution and produce a predictable rolling motion. They are ideal for straighter shots or controlled hooking, making them suitable for beginners and those looking for consistency. This type of weight block also has the widest range of RG/Diff number combinations.

Asymmetric

Asymmetric cores have an uneven weight distribution, resulting in increased hook potential and more aggressive reactions on the lane. Advanced bowlers often prefer asymmetric cores to generate powerful hooks.

Great Balls for Any Skill Level

These bowling balls are designed to be true all-rounders, offering a blend of performance, consistency, and adaptability that makes them ideal choices for both beginners and seasoned pros.

Use the filters below to refine the selection

INSIGHTFUL TIPS

Want to learn more about bowling balls? Check out this content on lane play and ball motion

7 min read

7 min read

7 min read

7 min read

EXPLORE MORE

Explore videos and other content